Uudised

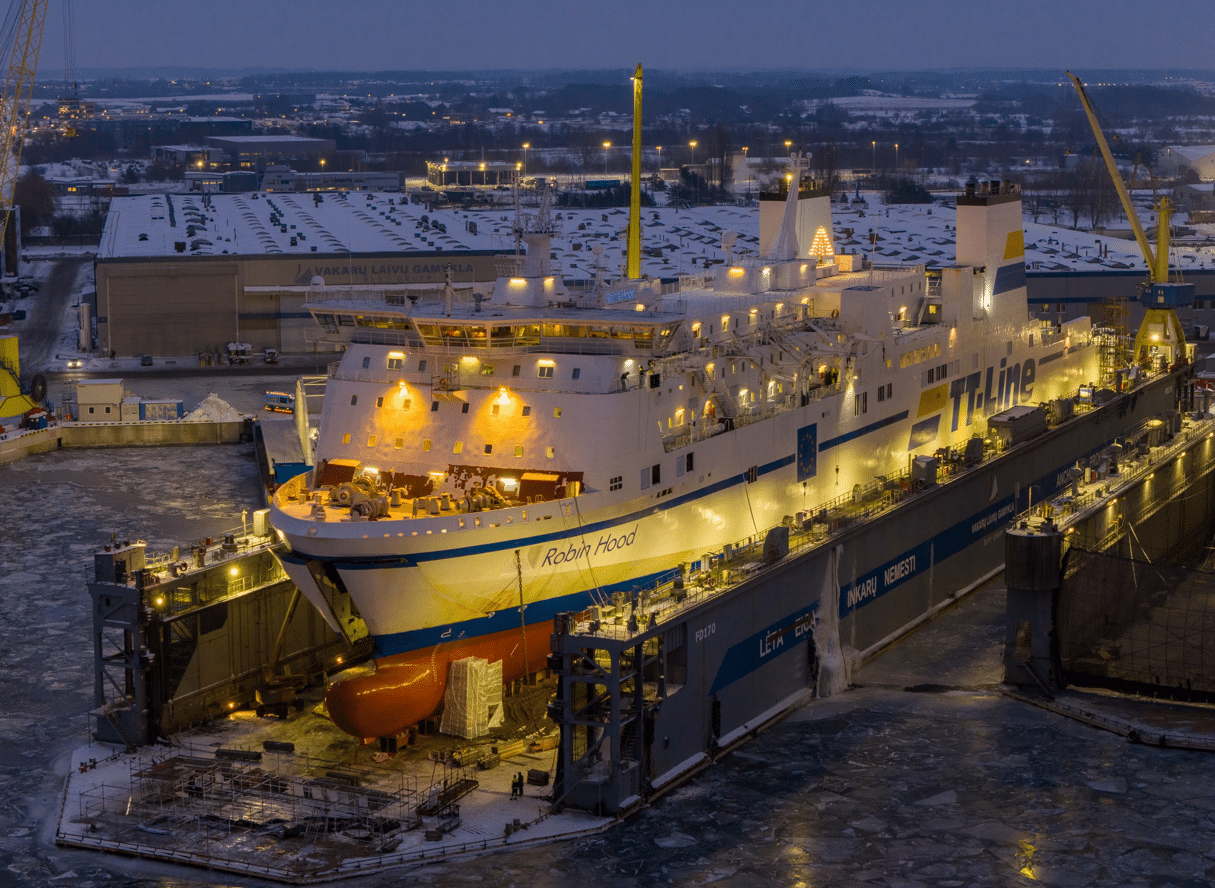

Ferry Robin Hood of TT- Line has now departed our yard in Klaipeda, following a scheduled maintenance focused on protection, safety, and operational reliability.

A familiar name, carrying a legacy of endurance and reliability- qualities that matter just as much in modern ship repair.

During her stay, the focus was on restoring safety and mechanical readiness. Underwater hull painting was carried out using the XGIT-Fuel 3.0 coating system by X-GIT Coatings, with full sheltering of the underwater area to ensure controlled temperature and humidity conditions, a critical factor for coating quality and long-term efficiency.

Beyond performance, such an application represents a meaningful step towards the sustainability ambitions shaping today’s ferry operations, supporting efficiency improvements and reduced environmental impact over the vessel’s operational lifecycle.

Above the waterline, Deck 1 underwent grit blasting and repainting with a PPG coating system with the addition of antiskid aggregate from PPG. In ship repair terms, this means a fully specified, multi-layer coating solution, from surface preparation through primers, intermediate coats, and topcoat, applied to protect steel and restore durability.

The scope was completed with maintenance and adjustment of all ramps, minor steel repairs, cleaning and painting of topside and superstructure areas, piping works, servicing of rudders, propellers, and bow thruster, inspection of tanks, maintenance of overboard valves and strainers, and cleaning of heat exchangers, alongside other related service and repair works.

With serviced and verified systems, Robin Hood has left the yard, ready for efficient and compliant service ahead, following a necessary maintenance pause to ensure continued operational readiness.